- Topic: Best solder for electronics in the USA (2026 guide)

- Best for: Circuit boards, wires, small repairs, DIY electronics

- Solder types: Lead-free, leaded, rosin-core, no-clean

- Wire size: 0.5mm–1.0mm for most board work

- Updated: 2026

Choosing the best solder for electronics starts with one goal: clean joints that hold up over time. The right solder flows well, bonds fast, and leaves less mess on the board.

This 2026 list is written for home projects in the USA, from small PCB repairs to wire splices. You’ll also see which solder types fit different jobs, so you can buy the right spool the first time.

| Solder | Type | Alloy | Wire Size | Best Use | Approx. Price (USD) |

|---|---|---|---|---|---|

| Kester 63/37 Rosin Core | Leaded | Sn63/Pb37 | 0.8mm | Fine PCB work, fast flow | $20–$35 |

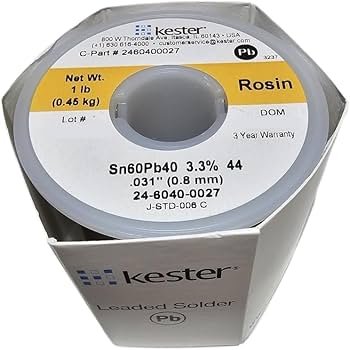

| Kester 44 Rosin Core 60/40 | Leaded | Sn60/Pb40 | 0.8mm | General electronics repairs | $18–$30 |

| MG Chemicals Lead-Free Rosin Core | Lead-free | SAC (Tin/Silver/Copper) | 0.8mm | RoHS-style work, cleaner handling | $22–$40 |

| AIM SAC305 Lead-Free | Lead-free | SAC305 | 0.8mm | Stronger lead-free joints | $25–$45 |

| Kester 245 No-Clean | Lead-free | SAC blend | 0.8mm | Low residue boards | $28–$50 |

Best Overall Solder for Electronics

Kester 63/37 Rosin Core (Sn63/Pb37)

If you want fast flow and smooth joints, this is a strong pick. The 63/37 mix melts and sets quickly, which helps reduce “cold joint” issues on small pads and fine wires.

It also works well for beginners because it tends to flow with less fighting. Pair it with a steady iron and a clean tip for better results. If you need an iron upgrade, see the best soldering iron for electronics.

Best Budget Solder for Electronics

Kester 44 Rosin Core 60/40 (Sn60/Pb40)

This solder is a solid choice when you want good results without paying extra. It flows well for most basic PCB repairs, wire tinning, and connector work.

It’s also easy to find in the USA, which helps when you need a quick refill. For general hobby use, 0.8mm is a good all-around size that still gives control on small pads.

Best Lead-Free Solder for Electronics

MG Chemicals Lead-Free Rosin Core (SAC)

If you prefer lead-free solder, this option is widely used for home electronics work. It handles most boards well when your iron is hot enough and your surfaces are clean.

Lead-free solders often need a bit more heat than leaded types. Use flux when needed, and keep contact time short to protect pads. This matters even more when you repair PC parts in the USA, like fans and connectors. For airflow-related builds, the best cooling fans for pc can help your setup run cooler after repairs.

Best Lead-Free Solder for Strong Joints

AIM SAC305 Lead-Free

SAC305 is a common lead-free alloy that can produce tough joints when done right. It’s a good fit for boards that see heat cycles, light vibration, or frequent plug-in use.

Because lead-free needs higher heat, a stable iron matters. Use a clean tip, add flux if the joint looks dry, and let the solder flow before you pull away.

Best No-Clean Solder for Low Residue Work

Kester 245 No-Clean

If you want less residue on the board, no-clean solder can make cleanup easier. This is helpful for tight boards, small parts, and work where you do not want to scrub around tiny pins.

No-clean does not mean “never clean.” If you see sticky buildup, cleaning is still a good idea. For PC work, you may also handle thermal parts during repairs. If you do GPU maintenance, the best thermal paste for the GPU can be useful after soldering-related fixes.

How to Pick the Best Solder for Electronics

Choose based on what you solder most often:

- For small PCB work: 0.5mm–0.8mm rosin-core wire

- For thicker wires: 0.8mm–1.0mm wire

- For lead-free work: plan for more heat and add flux when needed

- For cleaner boards: no-clean can help, but check the residue after cooling

FAQs

0.8mm is a strong all-around choice for most home electronics. Use 0.5mm for tiny pads and fine pins.

Lead-free is a good choice if you want to avoid lead, but it usually needs more heat and steady technique.

Yes. Rosin-core is made for electronics and helps the solder flow on clean pads and wires.

DISCLAIMER:

This blog post is for informational purposes only. We make every effort to provide accurate, current, and well-sourced information, but we cannot guarantee its completeness or absolute accuracy.

All images, videos, and logos used on this page belong to their respective owners. We aim to credit and reference them appropriately. If you are the rightful owner and wish to have your image, video, or logo removed, please contact us.

Author

-

Hey there! I'm Andrew Reed, and I live for the thrill of writing reviews. Dive into my world at bestfordaily.com, where I unpack stories behind products and experiences. I'm all about sharing my unique take on things, infusing each review with my youthful enthusiasm and a dash of social flair. Join me on this exciting journey—I promise you won't just read reviews; you'll experience them!

View all posts